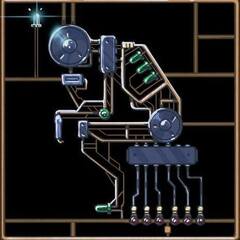

Intel 18c HEDT Die Pictured, Not Soldered (7980XE)

-

Topics

-

Shadeamous ·

Posted in Networking0 -

0

-

sturedoc ·

Posted in Cases and Mods0 -

3

-

TurboTrym ·

Posted in Troubleshooting2 -

2

-

brutalness ·

Posted in LTTStore.com Merch3 -

2

-

2

-

Berries ·

Posted in Graphics Cards2

-

-

play_circle_filled

Latest From Linus Tech Tips:

AMD Is Copying The Worst Thing About Intel - WAN Show May 31, 2024

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now