-

Posts

231 -

Joined

-

Last visited

Reputation Activity

-

Rosinbole reacted to RasmusDC in B L A C K B I R D

Rosinbole reacted to RasmusDC in B L A C K B I R D

could integrate 4 magnets in the front white mounts, so you could have a sheet metal part cut out as a front mesh, with a design, if you wanted to protect the fanblades, and to change the look..

it looks GREAT.

-

Rosinbole reacted to Klefth in B L A C K B I R D

Rosinbole reacted to Klefth in B L A C K B I R D

Wow, this thing is BEAUTIFUL. Great job. Also, that tiny rad is adorable and it's given me some ideas... ?

-

Rosinbole got a reaction from Klefth in B L A C K B I R D

Rosinbole got a reaction from Klefth in B L A C K B I R D

I've built and used the PC in the state it was in in the original post for quite a bit (even though I haven't been good at updating the build logs), and I've made quite a bit of changes - both performance and usability wise. Among the changes are:

A completely new front panel design allowing for substantially larger fans and incredibly improved airflow. Top and bottom covers on two structural pieces instead of single solid panels on the top and bottom. This eases assembly by a considerable amount.

I'm also thinking about adding the GPU into the loop by converting it into a single slot card with a waterblock and adding a slim 120mm rad with a 15mm fan behind it. One thing at a time though.

I'm waiting for some new hardware to fit on the new front panel design (should arrive in the coming week), so for now I've made a slideshow of the assembly to please your eyes. Because I'm only home in the weekends, I saw no use in building the entire PC to "completion" just to disassemble it again on saturday when I come home. This is only to give and idea of how the case is designed and built.

The case assembled

Notice that the screws holding the radiator assembly together are too long - this is because I'm waiting for thicker fans to arrive.

The assembly

Just for kicks, I laid most of the hardware and all of the case components out on the floor. Don't worry, no PCB's are touching carpet, and I took proper care when assembling the PC.

I will start by assembling the front panel. This is the lower front panel part in the new design with the powerbutton mounted.

The lower half of the radiator mount is mounted to the lower front panel assembly (had to split the rad mount because of my printers print volume).

The process is repeated for the upper half of the front panel.

Here comes the hard part. The front panel has to be assembles with the fans, fan covers, two halves of the front panel, and radiator all "floating" in 3D space before the parts can be secured with a set of long screws. With the new front panel design, I've made room for 25mm fans. Those will be put in when they come in the mail.

Now the top and bottom structural pieces must be assembled. For clarification, this is the top part.

Process is repeated with the bottom part.

Sidepanel mounts are assembled on to the top and bottom.

The case feet are mounted on the bottom panel.

The bottom structural piece can now be mounted to the front panel assembly.

The GPU-backplate is mounted on the bottom structural piece.

The back panel is mounted to the case.

The top structural piece is mounted to the case.

The motherboard tray is mounted to the case.

Struts are secured between the GPU-backplate and motherboard tray. This adds an incredible amount of stability.

Top cover is mounted on the case.

Bottom cover with the case feet attached is mounted on the case.

Motherboard is mounted.

GPU is mounted.

TG sidepanels are put on.

-

Rosinbole got a reaction from BiG StroOnZ in B L A C K B I R D

Rosinbole got a reaction from BiG StroOnZ in B L A C K B I R D

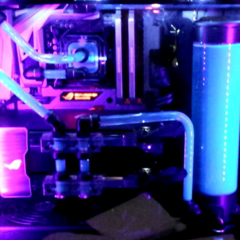

Changelog

* Slim Noiseblocker fans changed to new Noctua NF-A8 Chromax fans.

* Watercooling tubing has been sleeved.

* New and cleaner cable routing.

Upcoming changes

* New GTX 1070 with a bitspower water cooling block.

* Possibly the addition of an additional 120mm radiator in the system.

Pictures

New sleeved 6x10mm tubes.

Rad with the new Noctua fans. Note that the temporary fan grills have been taken off the fans in installing the rad, as they were in fact just temporary.

New sleeved tubes seen from the CPU side of the case.

New sleeved tubes seen from the GPU side of the case.

New routing for the fan cables.

New routing for the cables over the motherboard.

Finished build without panels attached.

Finished build seen from the GPU side.

Finished build seen from the CPU side.

Finished build up and running.

Cooling performance

I left the documentation on this PC (Blackbird), and next time I have access to it is in two weeks. I'm writing this from my laptop. You'll have to excuse me and trust my word.

Prime95:

A peak temp of 48C was reached after 15-20 minutes of 100% CPU load.

On about the 30 minute mark it settled on hovering from 43-45C, still at 100% load, and it seemed to become stable at this temperature range.

Due to the new Noctuas, the loop was dead silent too. I couldn't at all hear it over a light drizzle outside.

I'm very pleased.

-

Rosinbole got a reaction from BiG StroOnZ in B L A C K B I R D

Rosinbole got a reaction from BiG StroOnZ in B L A C K B I R D

I've built and used the PC in the state it was in in the original post for quite a bit (even though I haven't been good at updating the build logs), and I've made quite a bit of changes - both performance and usability wise. Among the changes are:

A completely new front panel design allowing for substantially larger fans and incredibly improved airflow. Top and bottom covers on two structural pieces instead of single solid panels on the top and bottom. This eases assembly by a considerable amount.

I'm also thinking about adding the GPU into the loop by converting it into a single slot card with a waterblock and adding a slim 120mm rad with a 15mm fan behind it. One thing at a time though.

I'm waiting for some new hardware to fit on the new front panel design (should arrive in the coming week), so for now I've made a slideshow of the assembly to please your eyes. Because I'm only home in the weekends, I saw no use in building the entire PC to "completion" just to disassemble it again on saturday when I come home. This is only to give and idea of how the case is designed and built.

The case assembled

Notice that the screws holding the radiator assembly together are too long - this is because I'm waiting for thicker fans to arrive.

The assembly

Just for kicks, I laid most of the hardware and all of the case components out on the floor. Don't worry, no PCB's are touching carpet, and I took proper care when assembling the PC.

I will start by assembling the front panel. This is the lower front panel part in the new design with the powerbutton mounted.

The lower half of the radiator mount is mounted to the lower front panel assembly (had to split the rad mount because of my printers print volume).

The process is repeated for the upper half of the front panel.

Here comes the hard part. The front panel has to be assembles with the fans, fan covers, two halves of the front panel, and radiator all "floating" in 3D space before the parts can be secured with a set of long screws. With the new front panel design, I've made room for 25mm fans. Those will be put in when they come in the mail.

Now the top and bottom structural pieces must be assembled. For clarification, this is the top part.

Process is repeated with the bottom part.

Sidepanel mounts are assembled on to the top and bottom.

The case feet are mounted on the bottom panel.

The bottom structural piece can now be mounted to the front panel assembly.

The GPU-backplate is mounted on the bottom structural piece.

The back panel is mounted to the case.

The top structural piece is mounted to the case.

The motherboard tray is mounted to the case.

Struts are secured between the GPU-backplate and motherboard tray. This adds an incredible amount of stability.

Top cover is mounted on the case.

Bottom cover with the case feet attached is mounted on the case.

Motherboard is mounted.

GPU is mounted.

TG sidepanels are put on.

-

-

Rosinbole reacted to Mbowen in B L A C K B I R D

Rosinbole reacted to Mbowen in B L A C K B I R D

Saw some of these picks on the Gunique discord the other day! Keep it up!

-

Rosinbole got a reaction from Arkratos in B L A C K B I R D

Rosinbole got a reaction from Arkratos in B L A C K B I R D

Introduction

Scratch built case specifications:

7.23L excluding raised sidepanels

8.97L including raised sidepanels

100% anodized CNC milled aluminum structure

- main structure will be entirely 12mm panels

- inside structure will be 3mm panels

2x 4mm thick tinted tempered glass panels

Entirely assembled with metric countersunk-

and metric thumb-screws

Hardware specifications:

Custom modded Asus X470-i motherboard

AMD Ryzen 7 2700x CPU

2X8GB of 3GHz G.Skill TridentZ RGB

Gigabyte GTX 1070 MINI ITX OC 8GB

Samsung 512GB 950 PRO M.2 NVME SSD

450W G-unique Archdaemon + unlimited brick combo as power supply

Watercooling loop:

Alphacool Eisbaer LT solo

Alphacool NexXxoS UT60 triple 80mm X-Flow Radiator

(3x) Noiseblocker NB-BlacksilentPRO PCP 4-pin PWM 80x15mm fans

Exclusively low profile koolance fittings

Koolance QD3 quick disconnect fitting for filling, topping off, and draining

Worry not, for the build log will soon begin!

Thanks to Josh of NFC for lending me his beautiful skyslot design for this project!

-

Rosinbole got a reaction from Arkratos in B L A C K B I R D

Rosinbole got a reaction from Arkratos in B L A C K B I R D

I've built and used the PC in the state it was in in the original post for quite a bit (even though I haven't been good at updating the build logs), and I've made quite a bit of changes - both performance and usability wise. Among the changes are:

A completely new front panel design allowing for substantially larger fans and incredibly improved airflow. Top and bottom covers on two structural pieces instead of single solid panels on the top and bottom. This eases assembly by a considerable amount.

I'm also thinking about adding the GPU into the loop by converting it into a single slot card with a waterblock and adding a slim 120mm rad with a 15mm fan behind it. One thing at a time though.

I'm waiting for some new hardware to fit on the new front panel design (should arrive in the coming week), so for now I've made a slideshow of the assembly to please your eyes. Because I'm only home in the weekends, I saw no use in building the entire PC to "completion" just to disassemble it again on saturday when I come home. This is only to give and idea of how the case is designed and built.

The case assembled

Notice that the screws holding the radiator assembly together are too long - this is because I'm waiting for thicker fans to arrive.

The assembly

Just for kicks, I laid most of the hardware and all of the case components out on the floor. Don't worry, no PCB's are touching carpet, and I took proper care when assembling the PC.

I will start by assembling the front panel. This is the lower front panel part in the new design with the powerbutton mounted.

The lower half of the radiator mount is mounted to the lower front panel assembly (had to split the rad mount because of my printers print volume).

The process is repeated for the upper half of the front panel.

Here comes the hard part. The front panel has to be assembles with the fans, fan covers, two halves of the front panel, and radiator all "floating" in 3D space before the parts can be secured with a set of long screws. With the new front panel design, I've made room for 25mm fans. Those will be put in when they come in the mail.

Now the top and bottom structural pieces must be assembled. For clarification, this is the top part.

Process is repeated with the bottom part.

Sidepanel mounts are assembled on to the top and bottom.

The case feet are mounted on the bottom panel.

The bottom structural piece can now be mounted to the front panel assembly.

The GPU-backplate is mounted on the bottom structural piece.

The back panel is mounted to the case.

The top structural piece is mounted to the case.

The motherboard tray is mounted to the case.

Struts are secured between the GPU-backplate and motherboard tray. This adds an incredible amount of stability.

Top cover is mounted on the case.

Bottom cover with the case feet attached is mounted on the case.

Motherboard is mounted.

GPU is mounted.

TG sidepanels are put on.

-

Rosinbole reacted to KzE in |||| |||| |||| |||| Wall PC Build Log |||| |||| |||| ||||

Rosinbole reacted to KzE in |||| |||| |||| |||| Wall PC Build Log |||| |||| |||| ||||

Finally I managed to take good photos of the finished build. Enjoy.

-

Rosinbole got a reaction from Hasle in B L A C K B I R D

Rosinbole got a reaction from Hasle in B L A C K B I R D

Introduction

Scratch built case specifications:

7.23L excluding raised sidepanels

8.97L including raised sidepanels

100% anodized CNC milled aluminum structure

- main structure will be entirely 12mm panels

- inside structure will be 3mm panels

2x 4mm thick tinted tempered glass panels

Entirely assembled with metric countersunk-

and metric thumb-screws

Hardware specifications:

Custom modded Asus X470-i motherboard

AMD Ryzen 7 2700x CPU

2X8GB of 3GHz G.Skill TridentZ RGB

Gigabyte GTX 1070 MINI ITX OC 8GB

Samsung 512GB 950 PRO M.2 NVME SSD

450W G-unique Archdaemon + unlimited brick combo as power supply

Watercooling loop:

Alphacool Eisbaer LT solo

Alphacool NexXxoS UT60 triple 80mm X-Flow Radiator

(3x) Noiseblocker NB-BlacksilentPRO PCP 4-pin PWM 80x15mm fans

Exclusively low profile koolance fittings

Koolance QD3 quick disconnect fitting for filling, topping off, and draining

Worry not, for the build log will soon begin!

Thanks to Josh of NFC for lending me his beautiful skyslot design for this project!

-

Rosinbole got a reaction from r2724r16 in B L A C K B I R D

Rosinbole got a reaction from r2724r16 in B L A C K B I R D

Introduction

Scratch built case specifications:

7.23L excluding raised sidepanels

8.97L including raised sidepanels

100% anodized CNC milled aluminum structure

- main structure will be entirely 12mm panels

- inside structure will be 3mm panels

2x 4mm thick tinted tempered glass panels

Entirely assembled with metric countersunk-

and metric thumb-screws

Hardware specifications:

Custom modded Asus X470-i motherboard

AMD Ryzen 7 2700x CPU

2X8GB of 3GHz G.Skill TridentZ RGB

Gigabyte GTX 1070 MINI ITX OC 8GB

Samsung 512GB 950 PRO M.2 NVME SSD

450W G-unique Archdaemon + unlimited brick combo as power supply

Watercooling loop:

Alphacool Eisbaer LT solo

Alphacool NexXxoS UT60 triple 80mm X-Flow Radiator

(3x) Noiseblocker NB-BlacksilentPRO PCP 4-pin PWM 80x15mm fans

Exclusively low profile koolance fittings

Koolance QD3 quick disconnect fitting for filling, topping off, and draining

Worry not, for the build log will soon begin!

Thanks to Josh of NFC for lending me his beautiful skyslot design for this project!

-

Rosinbole reacted to Zeuligan in [Sponsored] Angl3d Ti - Dual Custom Loop EKWB | ASUS ROG | be quiet! Dark Base Pro 900 | by Zeuligan

Rosinbole reacted to Zeuligan in [Sponsored] Angl3d Ti - Dual Custom Loop EKWB | ASUS ROG | be quiet! Dark Base Pro 900 | by Zeuligan

For me it is always extra fun to reach the backside of a project. It is fun, it gives me the opportunity to sleeve and it is a milestone that state that a project is close to the end.

I started in Fusion 360 to get a feel for what I wanted to make. Went fairly fast to reach something I felt could work. I guess the upside of doing my third consecutive project in the amazing be quiet! Dark Base Pro 900. Color scheme was set a long time ago.

Took the loose motherboard tray and went to work.

A few anoying rivets that always adds extra work. Took some measurements and masked for sawing.

No problem with this baby. Fast, straight, hazzle free. Love my Ryobi saw (thank you again Ryobi for the support).

Started with a quick prototype that I 3D printed. Extended the height for dual layers (ofc) and did some modifications to holes and fastening after testing with a custom 24 I had laying around. This will look good sanded down and printed on high quality settings.

All pieces done. Will make the backside look clean.

I got some happy comments on my manually created cable "plate" on project Zeuligan. Was extra fun to be able to 3D print a perfect one. Still just a test print (lesser quality), but needed a prototype for measurements.

So easy. Did I mention I just love my saw? ❤️

That will work just as intended, I like this idea for cable management very much. Should prob make more of this...

Not that much thinking needed as I had my concept from Fusion 360. Just had to check that I could bend the cables and that I ended up at the right place at the bottom. The MB-plate has 2 holes wide enough for 30ish cables. Not good to miss that opening.

After finding the right placement, distance it wasn't much more to it. Just drill all the holes and thread them.

Could finally use some of that expensive black matte car vinyl I bought as a test for the exterior before I decided to paint it instead. Will make for a nice contrast in finish and color.

Pretty happy with that end result tbh. The matte finish works well for both the texture of the 3D printed custom cable combs and the half shiny metal frame. Will make for a nice backdrop for the custom sleeved MDPC-X cables.

Speaking of that. First layer of the 24 pin ready. Will leave that as a teaser for next updated that will be all the cables sleeved (ran out of ATX pins (sigh)) and mounted on the backside. Hope it will look good.

-

Rosinbole reacted to Zeuligan in [Sponsored] Angl3d Ti - Dual Custom Loop EKWB | ASUS ROG | be quiet! Dark Base Pro 900 | by Zeuligan

Rosinbole reacted to Zeuligan in [Sponsored] Angl3d Ti - Dual Custom Loop EKWB | ASUS ROG | be quiet! Dark Base Pro 900 | by Zeuligan

I'm more than happy! Sometimes brands just go way beyond what could be expected even in the wildest dreams. Sometimes amazing people keep doing amazing things. When this happens at the same time you get Atila at EKWB. Thank you so much Atila and thank you so much EKWB for the support.

The perfect block for project Angl3d Ti just arrived. Got to test out my new Nikon FX as well -

Rosinbole reacted to Andyl in Scratch Build water cooled. Front distributor plate.

Rosinbole reacted to Andyl in Scratch Build water cooled. Front distributor plate.

Here is my other custom build from scratch enclosure project. I started this project in June 2017. I wanted an air cooled case that could take a full size ATX motherboard, power supply and full size graphics cards. However with no 3.5" drives, optical drives or water cooling to keep it light weight and quiet.

CPU: Intel Core i7 8700K Motherboard: ASUS ROG STRIX Z370-E Cooler: be quiet Dark Rock Pro 3 Memory: 16GB (2x8GB) Corsair DDR4 Vengeance LPX Black, PC4-19200 (2400) M.2 SSD: Samsung 250GB 960 Evo PCIe NVMe GPU: ASUS STRIX GTX980 4G DirCU2 OC PSU: Seasonic PRIME Ultra 850W 80+ Platinum Power Supply Rear Fan: Corsair 120mm ML Series ML120 Front fans 2x Corsair 140mm ML Series ML140 White LED Carbon Fiber Side Panels Graphite Powder Coat

-

Rosinbole reacted to Andyl in Scratch Build water cooled. Front distributor plate.

Rosinbole reacted to Andyl in Scratch Build water cooled. Front distributor plate.

Good catch. It was meant to be the other way round but as it is machined upside it got flipped. When I was looking a the CAD and the CNC program I forgot that and so it looked fine.

I stick it down with strong double sided tape on the release liner on the cosmetic side of the carbon fibre. I do like the resultant pattern though it looks a lot like a gas burner. If I make it again I think I will just add the extra arms.

-

Rosinbole reacted to CiBi in Scratch Build water cooled. Front distributor plate.

Rosinbole reacted to CiBi in Scratch Build water cooled. Front distributor plate.

Did you accidentaly mirror the blueprint or was it meant like this?

-

Rosinbole reacted to Giganthrax in Scratch Build water cooled. Front distributor plate.

Rosinbole reacted to Giganthrax in Scratch Build water cooled. Front distributor plate.

That is absolutely impressive. ❤️

-

Rosinbole reacted to Andyl in Scratch Build water cooled. Front distributor plate.

Rosinbole reacted to Andyl in Scratch Build water cooled. Front distributor plate.

Here is my scratch build.

Also check out this 3D design tool I made for laying out custom scratch builds. PC Design Foundry

You can select all sorts of components and move them around. You can plan out hard line water cooling and can download files as X3D.

I wanted a medium tower size with good air flow bottom to top. I also wanted to have a distributor plate on the front so there are no vent openings to keep it quiet.

I moved the power supply to the front of the enclosure and used an SFX form factor to get a good fit with the pump. Then I was able to fit two 360 rads along the whole length of the enclosure.

I used a Micro ATX motherboard because I was not going to need 7 PCI slots.

Looking back on the build I wish I had got a motherboard with built in RGB LED headers as I ended up having to get separate cables with built in controllers for the LED's in the Fans.

I also should change the connection from the pump to the front distributor plate to be a soft line tube at some point to minimise the bump vibration noise.

CPU. Intel i7 9700k GPU Palit RTX 2080Ti Samsung 970 EVO Polaris 500GB M.2 Kingston HyperX Predator RGB 16GB (2x8GB) DDR4 3200MHz Asus ROG Strix Z370-G Gaming (Wi-Fi AC) Micro-ATX 800W Silverstone Strider SFX Power Supply 2 x 360 Alphacool NexXxoS XT45 Radiators 6x EK Vardar 120 mm fans. EK Water Blocks EK-XRES 140 DDC 3.2 PWM Pump Bitspower Matte Black Fittings Custom sleved internal cabling

Machined corner extrusions form 1" square stock Aluminum 6082 on my Stoney CNC JBEC 1259012 router

Installed Tappex M4 inserts so that the other enclosure parts can be assembled. I tried M3 inserts but the installation toosl kept breaking.

Machined the sheet metal parts form 2 mm 6082 T6 Aluminium Stoney CNC JBEC 1259012 router The bed size is 1.25 m by 0.9 m with a vacuum table installed.

Folded using Baileigh Industrial, Magnetic Box and Pan Folder I have to machine a recess at the bend points to get really curate bends and avoid cracking.

Press in PEM inserts using Baileigh Industrial, BENCH PRESS (BP-3) These are the main motherboard mounting standoffs.

Start assembly test.

Machine first part of front distributor plate from 10 mm Cast Acrylic

Tap holes for G1/4 fittings

Test assembly fit check.

Some components

Fit check. I really wanted to have both the radiators and pump mount directly to the distributor plate with adjustable fittings instead of any additional hard line tubing.

Make some custom O rings.

The top fans are exhaust fans so I had to make a trim part to cover the rear labels.

Powder coated. I used an outside supplier for this.

Hand sand a brushed aluminum finish on the corner extrusions. I tried using a sander but it gouged the metal too much.

Bottom fans are intake. A bit of a shame as you cant see the logos.

Build some custom cables. Since the power supply is up front I needed some really short ones.

Also sleved the pump cables.

Making some custom PCI power cables.

Make some hard line tubing. PET 16 mm

Machine a carbon fiber side panel and top fan trim. Machined in a water bath.

First boot.

-

-

-

Rosinbole reacted to Zeuligan in [Sponsored] Angl3d Ti - Dual Custom Loop EKWB | ASUS ROG | be quiet! Dark Base Pro 900 | by Zeuligan

Rosinbole reacted to Zeuligan in [Sponsored] Angl3d Ti - Dual Custom Loop EKWB | ASUS ROG | be quiet! Dark Base Pro 900 | by Zeuligan

It's always equal part joy and frustration when you reach the painting part of a project. It's the mark of getting close to assembly, but it's also a very time consuming and sometimes frustrating part. This time more then usual with two disasters.

With a new living situation I had to be creative to be able to paint. Not recommended to spray paint inside your appartement Designed a 3-way corner for regular electrical PVC pipes - 20mm and printed out 8 of them.

Makes it simple to put together a spray tent of varible size, for close to nothing. Just to wrap in painters plastic and spray away Placed my tent on my balcony and it worked over expectations. Just had to stay away from rainy or windy days. We have a lot of thoose in Gothenburg, so spent close to 2 weeks painting all the parts.

I started by adding a first coat of primer. This to make it easier to visually spot all the weak areas, where I had to fill in and where I had to take away to keep angles in my polygons. Adds an extra day or two as the primer has to be really dry before I can add Putty to it (or the paint and putty melts together and it's a real mess) but well worth it IMHO.

With a combination of a small printed calibration cube (20x20x20mm) and the bottom of a bic lighter wrapped in straps of 280 and 400 grain paper I spent the next 6 days doing nothing but sanding and reapplying Putty.

Better, but far from satisfied. Then disaster struck...

When carrying one piece from my spray tent I accidently droped it onto the other piece and they both broke in several pieces. Not easy to Acrifix on paint, so had to sand down and start all over on some edges. Very sad and frustrated, but still happy that I was neither on a deadline or that it was actually mendable.

Lost a few days, but got both pieces together again and reached the exciting part where I could add the first layer for finishing coating - matte black. Wasn't happy with the finish, so sanded down part of it, switched out the spray can nozzle and had a 2nd go.

Look at that! Black and with much better surface. Still not home, so went over it with 600 and 800 grit and added 2 more layers.

That matte varnish is sexy! Very matte even after just 1 layer and close to that car vinyl feeling I wanted from start. Super happy. The extra matte black paint on the front piece suddenly looks super shiny in comparison.

At first I was scared that I had ruined it. The varnish was so white, even at super thin layers, but after 45-60min it just started to turn black and after just 30 min it turned from white to matte black.

Tripple matte awesomeness. Looking forward to when I can start to put this together.

After the exterior it was time to paint the shroud and 3D-printed parts. Smaller, but way more time consuming due to 10 times more edges. Same procedure, primer, putty, sanding, putty, sanding, putty, primer, spray putty, sanding, primer, spray putty, primer, sanding, coating, sanding, coating, coating, varnish, varnish and last a varnish.

Disaster 2, apparently butter fingers. Droped my shroud on the way in from the balcony, 5 pieces (cry).

If you have any questions, please feel free to ask anything. If you hate it or love it, share your thoughts. Silence worries me...

-

-

Rosinbole reacted to Zeuligan in [Sponsored] Angl3d Ti - Dual Custom Loop EKWB | ASUS ROG | be quiet! Dark Base Pro 900 | by Zeuligan

Rosinbole reacted to Zeuligan in [Sponsored] Angl3d Ti - Dual Custom Loop EKWB | ASUS ROG | be quiet! Dark Base Pro 900 | by Zeuligan

After a new modding room and a full stack of amazing tools thx to Ryobi I could get back to modding and project Angl3d Ti. Some parts left to do on the complicated front as well as closing up the bottom and front.

It was suddenly a dream. The last 3 angles to finish the front took 20min to finish instead of 200min. The saw and sander from Ryobi are monsters. Surprisingly quiet, but so powerful.

This is the last problem area left to do. Joining the bottom piece with the front piece.

Fast work at the new saw and some sanding

And we had a match. Left the piece a little big by choice, need to file it into perfect size to ensure an unvisible joint with the front.

Two larger pieces was all that was left to close up the bottom.

One final test fit before I added the pieces to the bottom. Then I will have to spend a few days sanding...

I spend almost the next week finishing up the 3 pieces. Just not sanding, but filling in all small gaps and uneven surfaces. The large beige section is plastic wood. Had to make up for a less perfect piece, but now it's even and smooth.

Will be so much fun turning this into black matt finish. Exterior is close to finish. Probably got 2 weeks left, sanding down the 3 front holes to perfect shape and size and then desining and 3D-print all the mesh pieces. Need to learn how to print and design...

Merry Christmas everyone

-

.jpg.84a17a3988ce123f559031e2342c4856.jpg)